vette

Darth Vader

Offline

I'm going to jump in here with both feet and stick my neck out real far so you all can cut it right off.

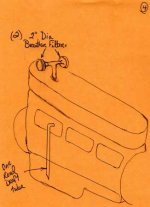

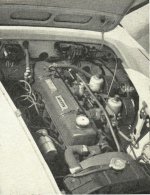

In finishing up my engine installation I have been looking at the possible installation of a PCV valve. I'm going to try to attach a drawing representative of the factory crankcase ventilation of my BJ7. Just for reference. To be honest with you I don't see how it could work. On contemporary engines and I believe on all engines, if there is a hose going from a valve cover to the air cleaner, this is the air inlet into the crankcase. This is not suction, but air inlet. The hose going from a valve cover , with a PCV valve in it, to the intake system "BELOW THE THROTTLE PLATES" is the suction. It you are going to draw air out of the crankcase you have to have another openning to the crankcase to allow air in so that there is a free exchange of atmosphere. As you can see on a contemporary engine, the hose stuck into the air cleaner is the air in, and the hose (with the PCV valve) stuck into the intake manifold below the throttle plates is the atmosphere being pulled out of the crankcase. So noting in the pic that the openning in the side tappet cover is plumbed to the openning at the top of the valve cover and then via the " T " plumbed on to the air cleaner, since that is air in, where is the circulation by air being drawn out. One last thought, "the best crankcase ventilation is no crankcase at all". Ok, boys: I'm holding my head, swing away. Dave.

In finishing up my engine installation I have been looking at the possible installation of a PCV valve. I'm going to try to attach a drawing representative of the factory crankcase ventilation of my BJ7. Just for reference. To be honest with you I don't see how it could work. On contemporary engines and I believe on all engines, if there is a hose going from a valve cover to the air cleaner, this is the air inlet into the crankcase. This is not suction, but air inlet. The hose going from a valve cover , with a PCV valve in it, to the intake system "BELOW THE THROTTLE PLATES" is the suction. It you are going to draw air out of the crankcase you have to have another openning to the crankcase to allow air in so that there is a free exchange of atmosphere. As you can see on a contemporary engine, the hose stuck into the air cleaner is the air in, and the hose (with the PCV valve) stuck into the intake manifold below the throttle plates is the atmosphere being pulled out of the crankcase. So noting in the pic that the openning in the side tappet cover is plumbed to the openning at the top of the valve cover and then via the " T " plumbed on to the air cleaner, since that is air in, where is the circulation by air being drawn out. One last thought, "the best crankcase ventilation is no crankcase at all". Ok, boys: I'm holding my head, swing away. Dave.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.