I suppose the only thing more certain in this world than Brits loving warm beer (because they have Lucas refrigerators) is that British cars leak oil.

As proven by our Bugeye. We bought it with a freshly restored engine. The restorer didn’t think it needed one of those fancy-dancy new rear main oil seals. It didn’t leak: It poured. The restorer even talked up the idea of mounting a catch basin under the back of the engine.

Uh huh – NO.

The restorer had included one of BMC’s PCV Valves (a $64 item from Moss, or is it a $64 dollar question) in the rebuild, and it was plumbed correctly. Given I was already generating a small lake of oil on the garage floor I didn’t try running without to see if it made things worse. Instead, I pulled the engine with the intent of installing an external rear main seal.

As I was installing the new rear main seal, I found a sufficient number of “oops” to justify just doing a rebuild.

After looking at my options, I decided I might just as well go all-in and have MiniMania convert the 1275 to a 1380. Complete with rear main seal (and a few other goodies).

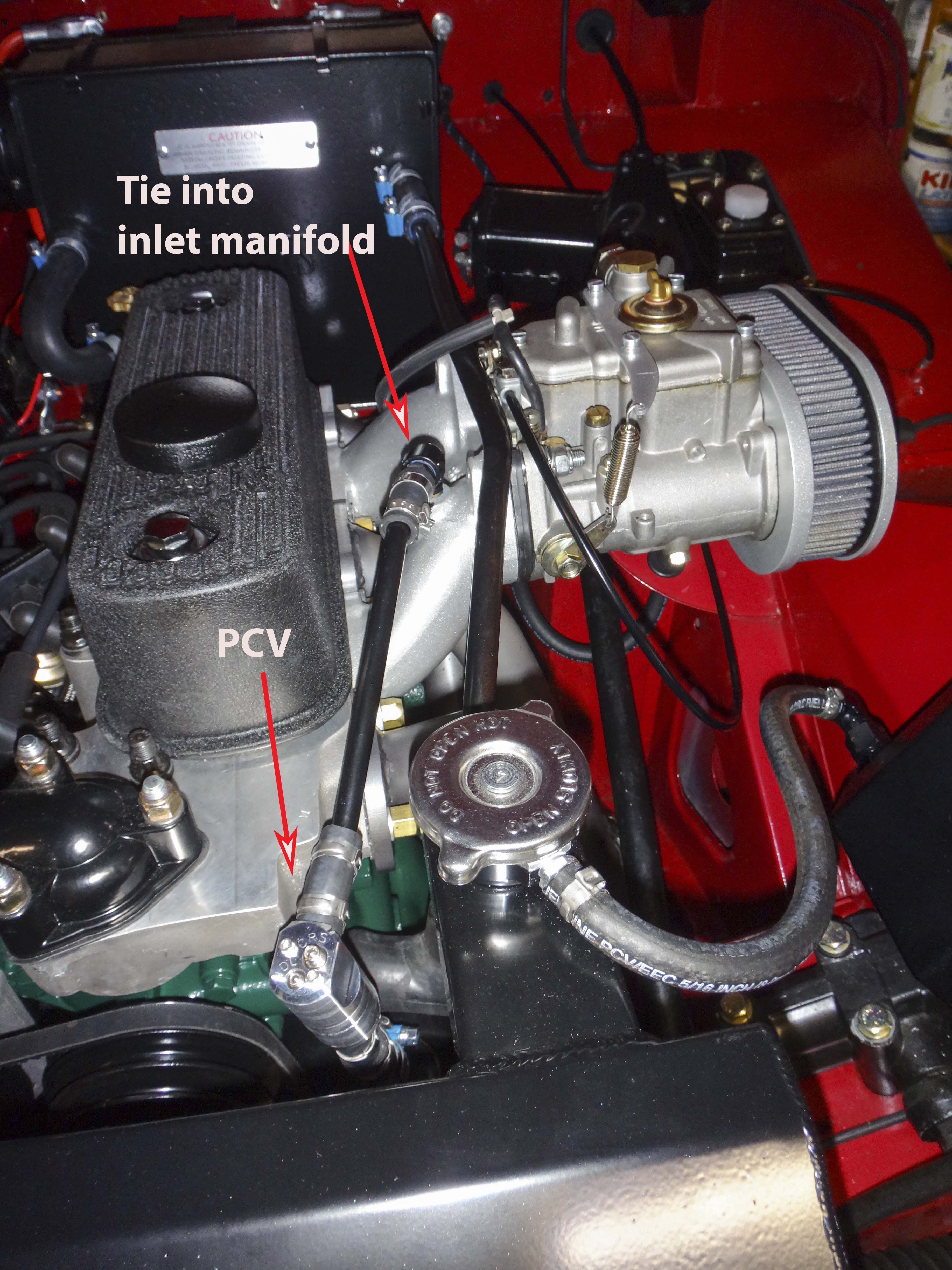

Time goes by and I receive the freshly rebuilt engine. I get it installed - here is a shot of the finished engine bay:

As you might suspect, still have a drip at the back of the engine. But it is much less than before.

Which brings me to the reason for this article.

The more pressure in the crankcase, the more leaks one will have.

Engines tend to leak combustion gasses into the crankcase. It’s called “blow-by”. If you don’t vent the crankcase the pressure will build until the crankcase vents itself. Which would not be a good thing. Easiest thing is to vent the crankcase into the air cleaner housing downstream of the air filter. Granted, there is precious little vacuum downstream of the air filter, so this method results in a bit of pressure in the crankcase. Which doesn’t help reduce leaks. Our ’69 XKE is an excellent example of this. Flip side, the underside of our XKE is rust free. Always tradeoffs, eh?

PCV valves are supposed to draw a slight vacuum in the crankcase – which should help reduce leaks. Additionally, engines with PCV valves also have a fresh air vent into the crankcase. In this way the PCV valve is supposed to not only create a small vacuum but also flush blowby out of the crankcase with the fresh air from the vent.

PCV valves self-regulate (mostly closed to fully open) based on the intake manifold vacuum. High vacuum (idling engine) = mostly closed. Low vacuum (hard acceleration) = fully open. Granted they don’t tend to adjust very accurately - similar to all season tires not being great in the summer or winter.

Over the years I have used an adjustable PCV valve made by M/E Wagner on cars that were somewhat less than stock. Or, perhaps a whole bunch of not stock. One had a bad habit of popping the dip-stick out of its tube and blowing smoke at odd moments from the rocker cover vent. Not good. And that was with the PCV valve that was spec’d for the block in its original configuration.

M/E Wagner’s PCV valve rectified the situation.

I figured, what the heck, let’s set up the 1380 with an M/E Wagner PCV valve.

My goal was to have a slight vacuum in the crankcase to keep oil from getting out of the crankcase. How much vacuum you might wonder? Well, turns out that is a good question. Found a Tech bulletin from BMW ( https://static.nhtsa.gov/odi/tsbs/2018/MC-10145282-9999.pdf ) that suggests vacuums in the range of 0.2 to 0.7 psi are good. Another outfit ( > What should my crankcase pressure be? [Updated!] < ) suggested that a PCV system should be pulling 0.5 to 1.5 psi in the crankcase at idle.

Others suggest that a few inches water gauge (think less than a tenth of a psi) is sufficient. In my experience, a few inches water gauge is not sufficient.

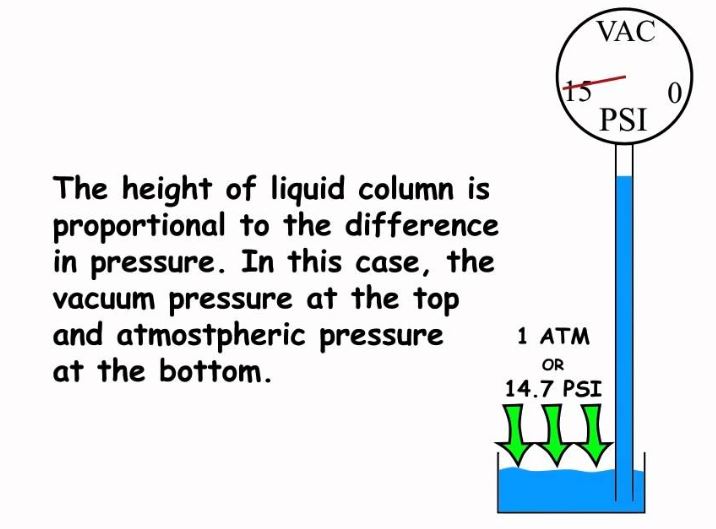

Ever tried sucking on a clear plastic tube to draw water an inch and a half up the tube. That is a mighty small vacuum. In comparison, a psi is what, 27 inches water gauge?

With these thoughts I started messing around with one of M/E Wagner’s adjustable PCV Valves.

What does a PCV valve do? It uses inlet manifold vacuum to draw a slight vacuum in the crankcase. Typically, the vacuum in an inlet manifold is in the 5 to 10 psi range. Lots of vacuum to pull gasses and fresh air from crankcase. BUT, pull too much from the crankcase and you will mess up your carb settings. My goal was to pull as little air as reasonable while focused on the psi or two of vacuum in the crankcase.

Note – I have used PSI as the predominant unit of pressure in this article. If you are used to thinking in terms of inches of mercury (as in “Hg), just double the psi numbers.

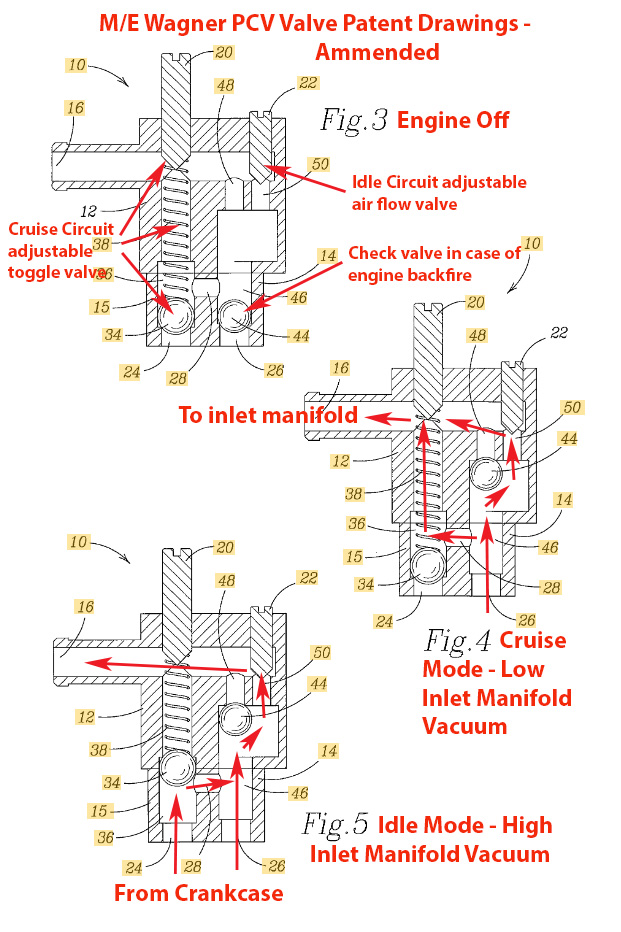

PCV valves usually have two modes of operation – one for high vacuum in the inlet manifold (at idle and light cruising) and a second for lower vacuum levels in the inlet manifold (higher speed cruising and acceleration).

If you have a mild cam, you likely have 9 or more psi vacuum at idle. Wild cam – well, likely less than 5 psi vacuum at idle. This is why PCV valves need to be matched to your specific situation. And why the PCV valve that I used on my 427 Roush – that was right for a stock 427 – was not a good fit for a 427 with a longer duration cam. With lots of overlap.

M/E Wagner’s adjustable PCV valve allows one to develop a custom fit for the specifics of the engine you are working on. Their valve has two modes of operation, what they call “cruise” (as in low inlet manifold vacuum) and “idle” (as in high inlet manifold vacuum). The idle circuit has more restriction than the cruise circuit – because the high inlet manifold vacuum at idle will draw more gasses from the crankcase. Their valve allows one to adjust the volume of gases extracted from the crankcase at idle and the inlet manifold vacuum level at which the cruise circuit cuts in.

Turns out M/E Wagner has given some thought to how much blowby plus purge air needs to be drawn from the crankcase in various engines. They have a nifty table giving the suggested idle circuit setting for various engines capacities and inlet-manifold vacuum levels. This gives a starting point for setting up their PCV valve.

A 1380 cc engine is pretty much at the bottom of their valve’s range of idle settings.

A side track for a moment. Let’s see – we want to draw a vacuum on the crankcase. What would make it hard to draw a vacuum? Well, anything that lets air into the crankcase. In my first attempt with the PCV valve I fitted a filter on the little k/o pot that MiniMania installed on the side of our 1380 – where the fuel pump otherwise would mount. Here is a shot of the air filter and k/o pot:

The k/o pot gave me a good place to install a filter on the fresh-air source for the crankcase. It’s sort of a good idea to have a fresh air inlet when using a PCV valve, otherwise you could be drawing a serious vacuum in your crankcase and burning lots of oil. The fresh air also acts to purge blowby and the associated water vapor that is the result of burning hydrocarbons.

I then installed the PCV valve on the vent from the k/o pot that is mounted to the timing cover of 1275 engines. Here’s a couple of shots of the installed PCV valve:

You might note that the PCV valve is tied into the inlet manifold for one half of the engine – in as much as this little gem came with a 40 DCOE. More on the implication of this later.

With the PCV valve tuned per M/E Wagner’s instructions there was 0.05 psi crankcase vacuum. Hmmm. That’s pretty low? In fact, you might wonder how I managed to measure a vacuum that low. If you have never used a water manometer – they are really handy for reading low pressures or vacuums. Manometer (plastic hose draped down into a bowl of water) showed 1.5 inches of water pulled up into the plastic hose. Which is about 0.05 psi vacuum.

Note, if you use a manometer, disconnect from the vacuum source before you lift the tube out of the water. If you lift the tube first you might get a small shot of water into the crankcase.

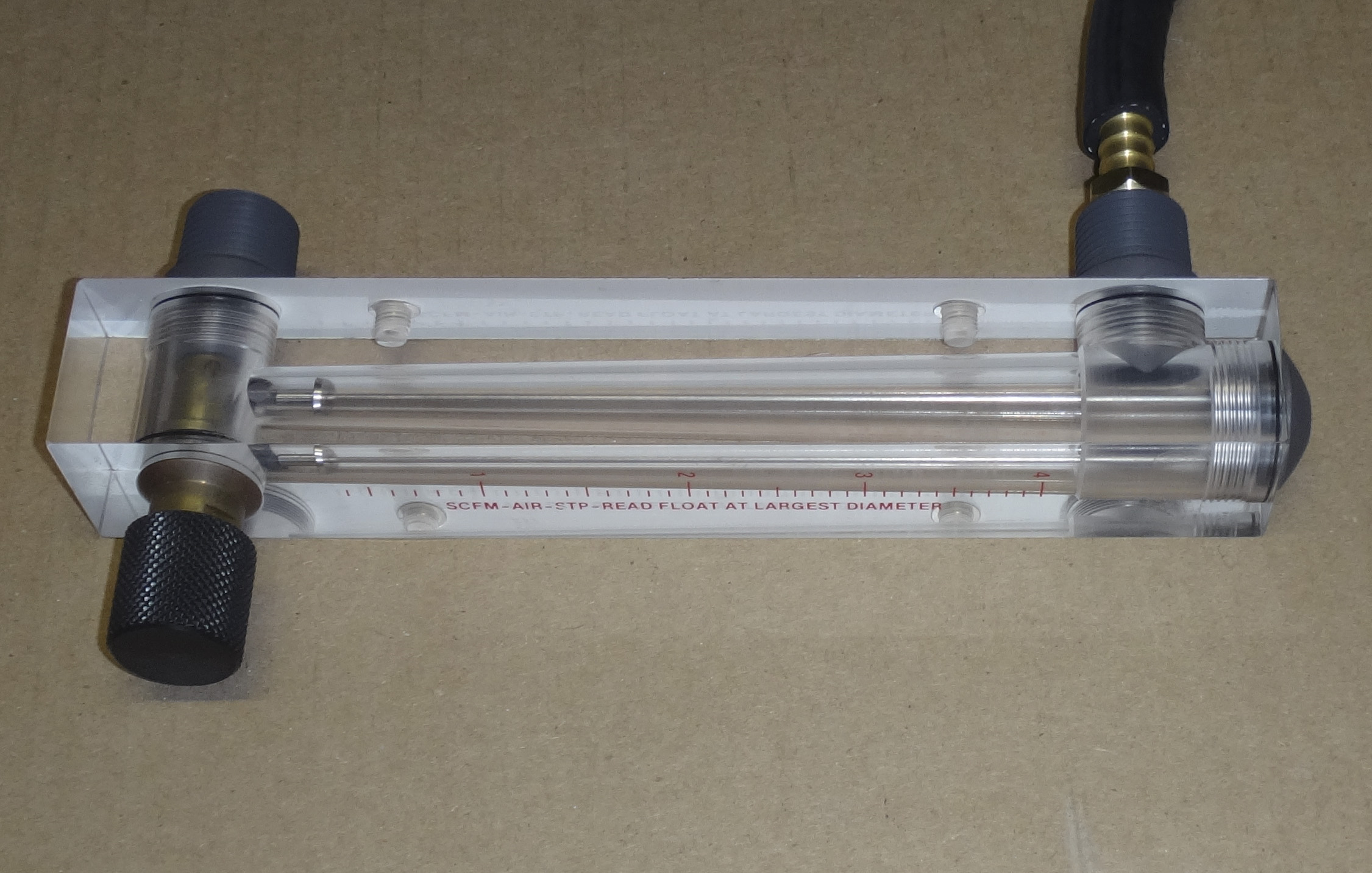

I also happened to have something called a rotameter – it is a nifty device that lets you read gas flow rates.

The rotameter showed I was pulling just over 1 scfm through the crankcase fresh-air vent. The car didn’t like this. A 1380 pulls around 2.25 scfm at idle. https://www.carparts.com/blog/symptoms-of-failing-mass-air-flow-sensor/ This mean the two branches of the inlet manifold each flow about 1.1 scfm – which is about how much air I was seeing through the rotameter. The engine was not happy with 2 cylinders running on crank-case gasses diluted with fresh air.

Granted, the gas in the crankcase contains unburnt hydrocarbons (both gasoline and oil), but still, drawing 50% of the air an engine needs at idle is not an optimal solution, especially in that (in my case) all that air is going into just half of the engine.

Let’s see – target is 1 to 2 psi vacuum, and we can’t pull more air through the PCV valve and expect the engine to idle. What to do???

Given that M/E Wagner provides an initial setting for the idle circuit air flow for various engines, I decided to use that setting as the basis for figuring out how to get 1 to 2 psi vacuum in the crankcase.

If you can’t increase the amount you pull from the crankcase, you can sure decrease the amount of air that goes into the crankcase.

Digression one more time. The dipstick in the little BMC 4-cylinder engine is pretty much a metal rod stuck into a plastic tube. It is not sealed. Turns out this is a heck of an air leak into the crankcase. For that matter, the nifty cap that MiniMania provided for the nifty rocker cover has a hole in the top of it – roughly 1.8 mm in diameter. Which actually leaks a lot of air. Funny, I was talking to one bugeye owner with the same cap on his 1275. He was complaining that the little vent hole sprayed oil on the underside of his bonnet. With a standard PCV valve. Hmmm. No vacuum there.

I plugged the cap vent hole, and added a tapered rubber plug to the dipstick to seal the dip-stick air leak.

Another aside, the easiest place to check the crank-case pressure/vacuum is via the dipstick tube. Shove a small-diameter rubber hose into the tube (with the dipstick removed) and you have a way to measure the crankcase vacuum with an appropriate gauge.

Next, I experimented with various size orifice plates (think washers) in the hose going to the crankcase fresh air filter. My goal was 1 to 2 psi vacuum and a much lower crankcase gas flow to the inlet manifold. After a bit of experimenting, I came down to a 2.0 mm hole in the orifice plate:

The orifice plate resulted in just under 2 psi vacuum and roughly 0.6 scfm being drawn through the crankcase fresh air filter. Fortunately, the engine now idled nicely (as nice as one would hope given its cam has an attitude).

We road tested the car and saw consistent 2 psi vacuum while idling, cruising, and under light acceleration. Harder acceleration resulted in the crankcase dropping down close to no vacuum. Of course, under hard acceleration, the vacuum in the inlet manifold will drop down to near 0, so not much chance of drawing a vacuum on the crankcase.

When we got home there was no sign of any leakage on the underside of the back of the engine.

I then realized that I could possibly use the “idle” screw on the PCV valve to further reduce the flow from the crankcase – and drop the crankcase vacuum a little. Turns out with the idle screw almost closed (it was close already based on the recommended settings from M/E Wagner for such a small engine) I was able to reduce the vacuum to 1.75 psi and the flow to 0.5 scfm. I think this is the best I can do with their valve. And I am happy with this outcome.

One further thought. Whilst rather unlikely, it is not impossible to have the gasses in the crankcase explode. OK – from what I can research, this is a problem in big engines (think big marine engines) and is often caused by too much pressure in the crankcase. But, just to be on the safe side, it is not a bad idea to include some form of pressure relief in your design. In my case, I have left the clamp that holds the filter to the vent pipe from the crankcase reasonably loose – so that the filter will just blow off if there were ever a need. Flip side, if, in your application, the PCV valve is inserted into a grommet in the rocker cover – the PCV valve will pop right out if there is ever a need. Of course, the dip stick will also pop out.

And another thought – I read about folks installing oil k/o pots in the line from their PCV valve to their inlet manifold. The goal is to remove any entrained oil droplets that are pulled out of the engine by the PCV flow. Overall, one of my primary benefits to the way I have set up the PCV system on our 1380 is it minimizes the flow of gasses from the crankcase. Which minimizes velocities as well as entrainment. Flip side, please realize – the gasses from the crankcase contain vaporized oil – as in, not oil droplets but oil that has been turned into a gas. Whilst a k/o pot that is installed in a cool location will condense some of the vaporized oil and water vapor, it is pretty likely it will not condense all of the vapors – some will still be drawn into the inlet manifold. To me, the best solution is to minimize the gas flow from the crankcase whilst maintaining a slight vacuum in the crankcase.

If curious, the patent on M/E Wagner’s PCV valve gives a great discussion of how it works. > US9376945B2 - Two circuit adjustable PCV valve - Google Patents <

I’ve edited a couple of their figures to show the basics:

Now I am going to go back and fine-tune the system on our Roush 427 and install a system on our ’69 XKE. Not that the XKE leaks all that much, but it is also not dry – It’s a Jag.

I dearly hope this article makes sense. It is a complex subject, but I am very happy with the results of all this effort.

As proven by our Bugeye. We bought it with a freshly restored engine. The restorer didn’t think it needed one of those fancy-dancy new rear main oil seals. It didn’t leak: It poured. The restorer even talked up the idea of mounting a catch basin under the back of the engine.

Uh huh – NO.

The restorer had included one of BMC’s PCV Valves (a $64 item from Moss, or is it a $64 dollar question) in the rebuild, and it was plumbed correctly. Given I was already generating a small lake of oil on the garage floor I didn’t try running without to see if it made things worse. Instead, I pulled the engine with the intent of installing an external rear main seal.

As I was installing the new rear main seal, I found a sufficient number of “oops” to justify just doing a rebuild.

After looking at my options, I decided I might just as well go all-in and have MiniMania convert the 1275 to a 1380. Complete with rear main seal (and a few other goodies).

Time goes by and I receive the freshly rebuilt engine. I get it installed - here is a shot of the finished engine bay:

As you might suspect, still have a drip at the back of the engine. But it is much less than before.

Which brings me to the reason for this article.

The more pressure in the crankcase, the more leaks one will have.

Engines tend to leak combustion gasses into the crankcase. It’s called “blow-by”. If you don’t vent the crankcase the pressure will build until the crankcase vents itself. Which would not be a good thing. Easiest thing is to vent the crankcase into the air cleaner housing downstream of the air filter. Granted, there is precious little vacuum downstream of the air filter, so this method results in a bit of pressure in the crankcase. Which doesn’t help reduce leaks. Our ’69 XKE is an excellent example of this. Flip side, the underside of our XKE is rust free. Always tradeoffs, eh?

PCV valves are supposed to draw a slight vacuum in the crankcase – which should help reduce leaks. Additionally, engines with PCV valves also have a fresh air vent into the crankcase. In this way the PCV valve is supposed to not only create a small vacuum but also flush blowby out of the crankcase with the fresh air from the vent.

PCV valves self-regulate (mostly closed to fully open) based on the intake manifold vacuum. High vacuum (idling engine) = mostly closed. Low vacuum (hard acceleration) = fully open. Granted they don’t tend to adjust very accurately - similar to all season tires not being great in the summer or winter.

Over the years I have used an adjustable PCV valve made by M/E Wagner on cars that were somewhat less than stock. Or, perhaps a whole bunch of not stock. One had a bad habit of popping the dip-stick out of its tube and blowing smoke at odd moments from the rocker cover vent. Not good. And that was with the PCV valve that was spec’d for the block in its original configuration.

M/E Wagner’s PCV valve rectified the situation.

I figured, what the heck, let’s set up the 1380 with an M/E Wagner PCV valve.

My goal was to have a slight vacuum in the crankcase to keep oil from getting out of the crankcase. How much vacuum you might wonder? Well, turns out that is a good question. Found a Tech bulletin from BMW ( https://static.nhtsa.gov/odi/tsbs/2018/MC-10145282-9999.pdf ) that suggests vacuums in the range of 0.2 to 0.7 psi are good. Another outfit ( > What should my crankcase pressure be? [Updated!] < ) suggested that a PCV system should be pulling 0.5 to 1.5 psi in the crankcase at idle.

Others suggest that a few inches water gauge (think less than a tenth of a psi) is sufficient. In my experience, a few inches water gauge is not sufficient.

Ever tried sucking on a clear plastic tube to draw water an inch and a half up the tube. That is a mighty small vacuum. In comparison, a psi is what, 27 inches water gauge?

With these thoughts I started messing around with one of M/E Wagner’s adjustable PCV Valves.

What does a PCV valve do? It uses inlet manifold vacuum to draw a slight vacuum in the crankcase. Typically, the vacuum in an inlet manifold is in the 5 to 10 psi range. Lots of vacuum to pull gasses and fresh air from crankcase. BUT, pull too much from the crankcase and you will mess up your carb settings. My goal was to pull as little air as reasonable while focused on the psi or two of vacuum in the crankcase.

Note – I have used PSI as the predominant unit of pressure in this article. If you are used to thinking in terms of inches of mercury (as in “Hg), just double the psi numbers.

PCV valves usually have two modes of operation – one for high vacuum in the inlet manifold (at idle and light cruising) and a second for lower vacuum levels in the inlet manifold (higher speed cruising and acceleration).

If you have a mild cam, you likely have 9 or more psi vacuum at idle. Wild cam – well, likely less than 5 psi vacuum at idle. This is why PCV valves need to be matched to your specific situation. And why the PCV valve that I used on my 427 Roush – that was right for a stock 427 – was not a good fit for a 427 with a longer duration cam. With lots of overlap.

M/E Wagner’s adjustable PCV valve allows one to develop a custom fit for the specifics of the engine you are working on. Their valve has two modes of operation, what they call “cruise” (as in low inlet manifold vacuum) and “idle” (as in high inlet manifold vacuum). The idle circuit has more restriction than the cruise circuit – because the high inlet manifold vacuum at idle will draw more gasses from the crankcase. Their valve allows one to adjust the volume of gases extracted from the crankcase at idle and the inlet manifold vacuum level at which the cruise circuit cuts in.

Turns out M/E Wagner has given some thought to how much blowby plus purge air needs to be drawn from the crankcase in various engines. They have a nifty table giving the suggested idle circuit setting for various engines capacities and inlet-manifold vacuum levels. This gives a starting point for setting up their PCV valve.

A 1380 cc engine is pretty much at the bottom of their valve’s range of idle settings.

A side track for a moment. Let’s see – we want to draw a vacuum on the crankcase. What would make it hard to draw a vacuum? Well, anything that lets air into the crankcase. In my first attempt with the PCV valve I fitted a filter on the little k/o pot that MiniMania installed on the side of our 1380 – where the fuel pump otherwise would mount. Here is a shot of the air filter and k/o pot:

The k/o pot gave me a good place to install a filter on the fresh-air source for the crankcase. It’s sort of a good idea to have a fresh air inlet when using a PCV valve, otherwise you could be drawing a serious vacuum in your crankcase and burning lots of oil. The fresh air also acts to purge blowby and the associated water vapor that is the result of burning hydrocarbons.

I then installed the PCV valve on the vent from the k/o pot that is mounted to the timing cover of 1275 engines. Here’s a couple of shots of the installed PCV valve:

You might note that the PCV valve is tied into the inlet manifold for one half of the engine – in as much as this little gem came with a 40 DCOE. More on the implication of this later.

With the PCV valve tuned per M/E Wagner’s instructions there was 0.05 psi crankcase vacuum. Hmmm. That’s pretty low? In fact, you might wonder how I managed to measure a vacuum that low. If you have never used a water manometer – they are really handy for reading low pressures or vacuums. Manometer (plastic hose draped down into a bowl of water) showed 1.5 inches of water pulled up into the plastic hose. Which is about 0.05 psi vacuum.

Note, if you use a manometer, disconnect from the vacuum source before you lift the tube out of the water. If you lift the tube first you might get a small shot of water into the crankcase.

I also happened to have something called a rotameter – it is a nifty device that lets you read gas flow rates.

The rotameter showed I was pulling just over 1 scfm through the crankcase fresh-air vent. The car didn’t like this. A 1380 pulls around 2.25 scfm at idle. https://www.carparts.com/blog/symptoms-of-failing-mass-air-flow-sensor/ This mean the two branches of the inlet manifold each flow about 1.1 scfm – which is about how much air I was seeing through the rotameter. The engine was not happy with 2 cylinders running on crank-case gasses diluted with fresh air.

Granted, the gas in the crankcase contains unburnt hydrocarbons (both gasoline and oil), but still, drawing 50% of the air an engine needs at idle is not an optimal solution, especially in that (in my case) all that air is going into just half of the engine.

Let’s see – target is 1 to 2 psi vacuum, and we can’t pull more air through the PCV valve and expect the engine to idle. What to do???

Given that M/E Wagner provides an initial setting for the idle circuit air flow for various engines, I decided to use that setting as the basis for figuring out how to get 1 to 2 psi vacuum in the crankcase.

If you can’t increase the amount you pull from the crankcase, you can sure decrease the amount of air that goes into the crankcase.

Digression one more time. The dipstick in the little BMC 4-cylinder engine is pretty much a metal rod stuck into a plastic tube. It is not sealed. Turns out this is a heck of an air leak into the crankcase. For that matter, the nifty cap that MiniMania provided for the nifty rocker cover has a hole in the top of it – roughly 1.8 mm in diameter. Which actually leaks a lot of air. Funny, I was talking to one bugeye owner with the same cap on his 1275. He was complaining that the little vent hole sprayed oil on the underside of his bonnet. With a standard PCV valve. Hmmm. No vacuum there.

I plugged the cap vent hole, and added a tapered rubber plug to the dipstick to seal the dip-stick air leak.

Another aside, the easiest place to check the crank-case pressure/vacuum is via the dipstick tube. Shove a small-diameter rubber hose into the tube (with the dipstick removed) and you have a way to measure the crankcase vacuum with an appropriate gauge.

Next, I experimented with various size orifice plates (think washers) in the hose going to the crankcase fresh air filter. My goal was 1 to 2 psi vacuum and a much lower crankcase gas flow to the inlet manifold. After a bit of experimenting, I came down to a 2.0 mm hole in the orifice plate:

The orifice plate resulted in just under 2 psi vacuum and roughly 0.6 scfm being drawn through the crankcase fresh air filter. Fortunately, the engine now idled nicely (as nice as one would hope given its cam has an attitude).

We road tested the car and saw consistent 2 psi vacuum while idling, cruising, and under light acceleration. Harder acceleration resulted in the crankcase dropping down close to no vacuum. Of course, under hard acceleration, the vacuum in the inlet manifold will drop down to near 0, so not much chance of drawing a vacuum on the crankcase.

When we got home there was no sign of any leakage on the underside of the back of the engine.

I then realized that I could possibly use the “idle” screw on the PCV valve to further reduce the flow from the crankcase – and drop the crankcase vacuum a little. Turns out with the idle screw almost closed (it was close already based on the recommended settings from M/E Wagner for such a small engine) I was able to reduce the vacuum to 1.75 psi and the flow to 0.5 scfm. I think this is the best I can do with their valve. And I am happy with this outcome.

One further thought. Whilst rather unlikely, it is not impossible to have the gasses in the crankcase explode. OK – from what I can research, this is a problem in big engines (think big marine engines) and is often caused by too much pressure in the crankcase. But, just to be on the safe side, it is not a bad idea to include some form of pressure relief in your design. In my case, I have left the clamp that holds the filter to the vent pipe from the crankcase reasonably loose – so that the filter will just blow off if there were ever a need. Flip side, if, in your application, the PCV valve is inserted into a grommet in the rocker cover – the PCV valve will pop right out if there is ever a need. Of course, the dip stick will also pop out.

And another thought – I read about folks installing oil k/o pots in the line from their PCV valve to their inlet manifold. The goal is to remove any entrained oil droplets that are pulled out of the engine by the PCV flow. Overall, one of my primary benefits to the way I have set up the PCV system on our 1380 is it minimizes the flow of gasses from the crankcase. Which minimizes velocities as well as entrainment. Flip side, please realize – the gasses from the crankcase contain vaporized oil – as in, not oil droplets but oil that has been turned into a gas. Whilst a k/o pot that is installed in a cool location will condense some of the vaporized oil and water vapor, it is pretty likely it will not condense all of the vapors – some will still be drawn into the inlet manifold. To me, the best solution is to minimize the gas flow from the crankcase whilst maintaining a slight vacuum in the crankcase.

If curious, the patent on M/E Wagner’s PCV valve gives a great discussion of how it works. > US9376945B2 - Two circuit adjustable PCV valve - Google Patents <

I’ve edited a couple of their figures to show the basics:

Now I am going to go back and fine-tune the system on our Roush 427 and install a system on our ’69 XKE. Not that the XKE leaks all that much, but it is also not dry – It’s a Jag.

I dearly hope this article makes sense. It is a complex subject, but I am very happy with the results of all this effort.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>