Hi All,

I have been tracking down a low vacuum condition on my 1973 six. I get the most vacuum with all emissions ports plugged, including the brake booster(which was leaking). The carbs have been rebuilt, they and the motor run the abosolute best with the crankcase vent(from the valve cover)ports plugged. Doing this obviously leaves the vent tube from the valve cover open.

My questions are: 1) Would just a naked valve cover vent tube allow enough crankcase ventaltion?

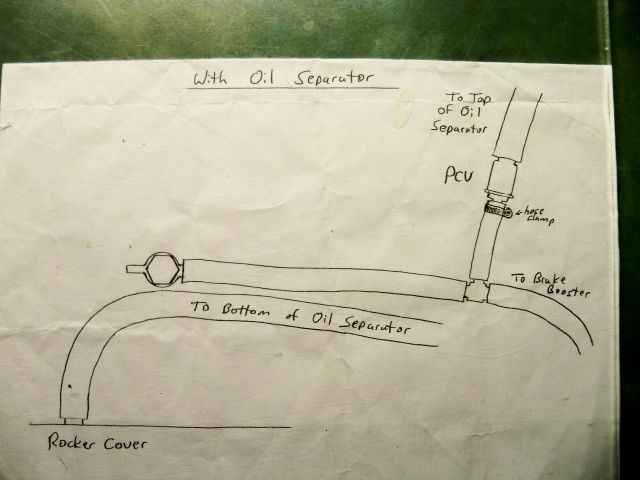

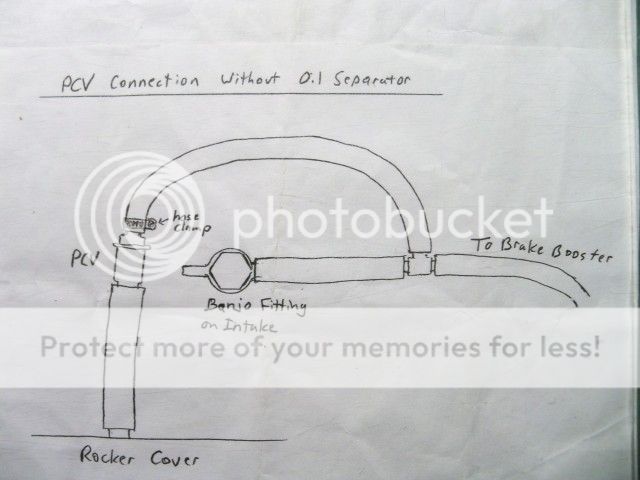

2) If I just ran the vent tube to one carb should I install a inline PCV? has anyone done this?

3) Being that the motor is supposed to be leak free ie: tight valve cover filler cap, sealed oil dipstick. where does fresh air enter the crankcase from?

Right now the motor runs (dare I say) perfect. The moment I start to re-plumb the emission hoses it begins to run crappy, so I know there is leaking going on in the hoses or the motor (hence the pcv idea) At this point it is basically a motor with two carbs on it and runs best, I have no problem leaving this way just concerned about crank ventilation.

Thanks for any help

Brain

I have been tracking down a low vacuum condition on my 1973 six. I get the most vacuum with all emissions ports plugged, including the brake booster(which was leaking). The carbs have been rebuilt, they and the motor run the abosolute best with the crankcase vent(from the valve cover)ports plugged. Doing this obviously leaves the vent tube from the valve cover open.

My questions are: 1) Would just a naked valve cover vent tube allow enough crankcase ventaltion?

2) If I just ran the vent tube to one carb should I install a inline PCV? has anyone done this?

3) Being that the motor is supposed to be leak free ie: tight valve cover filler cap, sealed oil dipstick. where does fresh air enter the crankcase from?

Right now the motor runs (dare I say) perfect. The moment I start to re-plumb the emission hoses it begins to run crappy, so I know there is leaking going on in the hoses or the motor (hence the pcv idea) At this point it is basically a motor with two carbs on it and runs best, I have no problem leaving this way just concerned about crank ventilation.

Thanks for any help

Brain

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>