Geo Hahn

Yoda

Offline

I just had a speedometer rebuilt and calibrated by one of the Big 3 firms that do this work. The work was needed to accommodate a change in the diff ratio. The results are mixed.

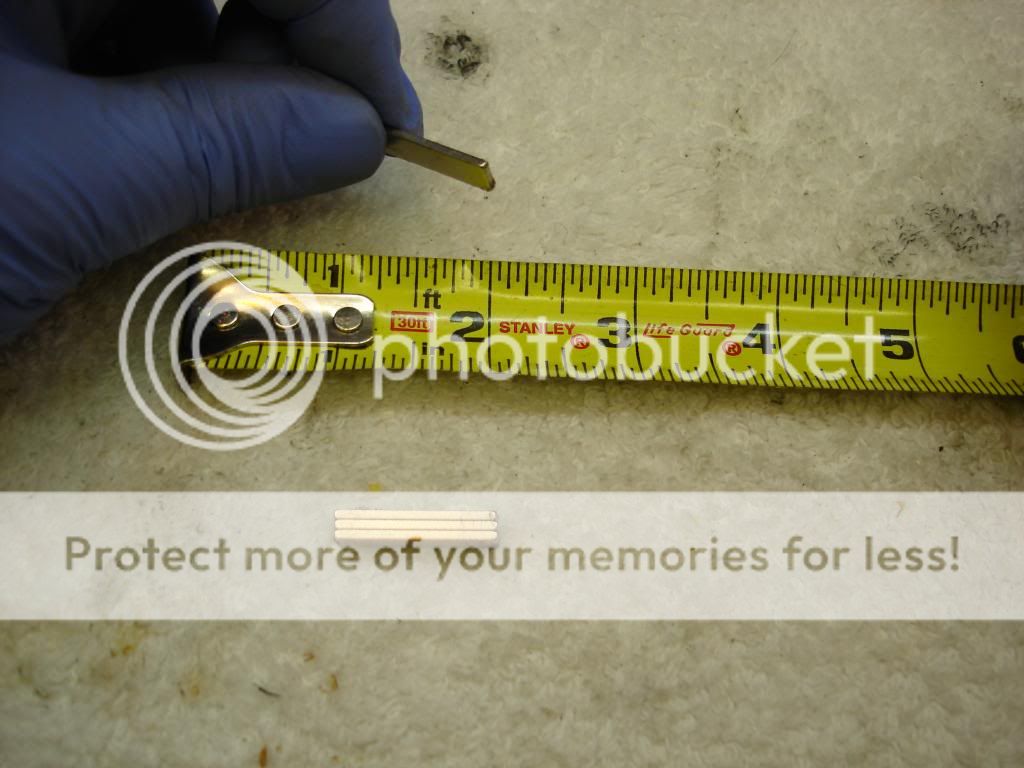

I did their prescribed test - roll the car 1/100 of a mile and count the cable turns. This part went well as the odometer is now accurate and the speedometer is accurate at 60 mph. This suggests to me that the unit was spun at the speed indicated by the roll test (cable turns x 100) and the unit either indicated (or was adjusted to indicate) 60 mph.

The problem is that the speedometer reads low (compared to a GPS) at low speeds - for example an indicated 35 is an actual 40, and indicated 40 is an actual 44, etc. It becomes correct at 61 mph and starts to read too high above that. I was limited in being able to test at very high speed as I was too far from a suitable stretch of road.

I thought this non-linear error meant an issue with either the strength of magnetism in the flying magnet or the strength of the spring. The reply from the rebuilder was this:

Are things as hopeless as that seems to suggest?

Is the strength or weakness of the flying magnet not a factor in this calibration?

I'm not criticizing the rebuilder at this point - just trying to understand if the limits of what they say can be done are, in fact, reasonable.

Disclosure: This is unit from a Jaguar, not a TR -- but the design is the same and I am asking here because this is where I usually find answers.

I did their prescribed test - roll the car 1/100 of a mile and count the cable turns. This part went well as the odometer is now accurate and the speedometer is accurate at 60 mph. This suggests to me that the unit was spun at the speed indicated by the roll test (cable turns x 100) and the unit either indicated (or was adjusted to indicate) 60 mph.

The problem is that the speedometer reads low (compared to a GPS) at low speeds - for example an indicated 35 is an actual 40, and indicated 40 is an actual 44, etc. It becomes correct at 61 mph and starts to read too high above that. I was limited in being able to test at very high speed as I was too far from a suitable stretch of road.

I thought this non-linear error meant an issue with either the strength of magnetism in the flying magnet or the strength of the spring. The reply from the rebuilder was this:

Because of the wide variation between the original and current calibration of the Speedo, any further fine tuning of the calibration is limited to weighting the pointer and playing with spring rates both of which will produce results that are in all honesty, a compromise, I.e., weighing the pointer will drop the Speed down at the lower range but will also slow it down in the upper range, changing out the drum spring to one with a higher rate will help solve this problem, however there are not a broad range of different spring rates available.

Are things as hopeless as that seems to suggest?

Is the strength or weakness of the flying magnet not a factor in this calibration?

I'm not criticizing the rebuilder at this point - just trying to understand if the limits of what they say can be done are, in fact, reasonable.

Disclosure: This is unit from a Jaguar, not a TR -- but the design is the same and I am asking here because this is where I usually find answers.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>