dondel

Freshman Member

Offline

Hi all,

I had last week lost of pressure on the clutch; with some problems I managed it back home. Before I lost the pressure, I noticed problems to change the gears which became later on impossible.

I checked the 2 Cylinders, which seem fine to me. I didn't notice any leaking of the pipes. Unfortunately, I couldn't open the bleed screw; so I couldn't air the system. (After a lot of chemical and brute force, I managed to open the screw )

)

1st question: how do you open the Master Cylinder to check if the rubber is still fine? I read somewhere in the forum that a member changed the rubber in the master cylinder, but I don't see where to open it. I managed to take off the "ring" and the "washer" but the rest seems to stay in the cylinder.

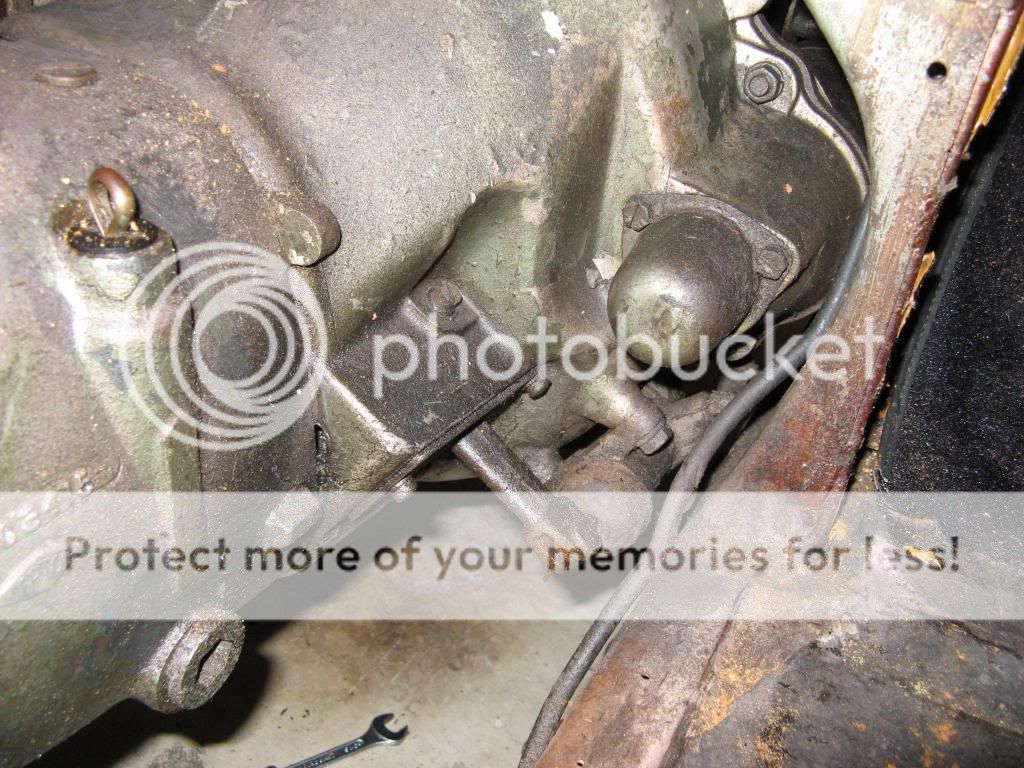

2nd question: I was wondering how the cylinders interacts with the clutch. At the RHD side of the gearbox, you have this so called clutch fork which is moved by the slave cylinder. At least on my BJ8, this fork is moving "freely" in both directions; no "resistance" or so is keeping it in one position. As the slave cylinder (different to the master) is not connected as such to the push rod, it cannot be pulled back by the cylinder it self. So is this free movement ability of the clutch fork correct or is there something broken?

I hope I was any clear and would be very grateful for your thoughts!!

I had last week lost of pressure on the clutch; with some problems I managed it back home. Before I lost the pressure, I noticed problems to change the gears which became later on impossible.

I checked the 2 Cylinders, which seem fine to me. I didn't notice any leaking of the pipes. Unfortunately, I couldn't open the bleed screw; so I couldn't air the system. (After a lot of chemical and brute force, I managed to open the screw

)

)1st question: how do you open the Master Cylinder to check if the rubber is still fine? I read somewhere in the forum that a member changed the rubber in the master cylinder, but I don't see where to open it. I managed to take off the "ring" and the "washer" but the rest seems to stay in the cylinder.

2nd question: I was wondering how the cylinders interacts with the clutch. At the RHD side of the gearbox, you have this so called clutch fork which is moved by the slave cylinder. At least on my BJ8, this fork is moving "freely" in both directions; no "resistance" or so is keeping it in one position. As the slave cylinder (different to the master) is not connected as such to the push rod, it cannot be pulled back by the cylinder it self. So is this free movement ability of the clutch fork correct or is there something broken?

I hope I was any clear and would be very grateful for your thoughts!!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Keoke

Keoke