B

Bobbee44

Guest

Guest

Offline

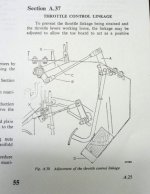

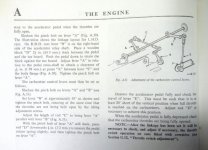

My 1960 3000 stopped dead late this summer. I coasted to the side of the street and could not get it started again after running through my complete list of potential culprits. The car was taken to the closest British car facility and kept for over a week. I was told the rotor was cracked and that was the reason the car had stopped dead. On driving the car from the repair facility, I noted the gas peddle was exceptionally stiff and the idle was very high (1200 rpm). I turned around and returned to the facility. The mechanic lifted the hood and showed me he had installed a spring to assist in keeping the idle low. I did not have any idle issues or return spring issues when I brought the car into the facility. Now, I have about two inches of throttle play as I push the gas peddle, before any change in engine rpm. The return spring at the gas peddle is in place.

I've made sure the two springs on each end of the carb linkage are tight and are not slipping. My question is simply this: What could the mechanic(s) done to the linkage to require an auxiliary spring, to a heretofore well operating system?

Any help in pointing me to a solution would be appreciated.

Bob

I've made sure the two springs on each end of the carb linkage are tight and are not slipping. My question is simply this: What could the mechanic(s) done to the linkage to require an auxiliary spring, to a heretofore well operating system?

Any help in pointing me to a solution would be appreciated.

Bob

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>